Author: Alison Phelan, Technical Consultant, Partel

What is a thermal bridge and where can it occur?

With energy costs rising, it’s important to consider what areas of your construction could be addressed to alleviate this. Early consideration of thermal bridge-free design during your build stage could lead to a considerable saving on energy bills and usage in the future. In addition, Passive House standard requires a thermal bridge ‘free’ design.

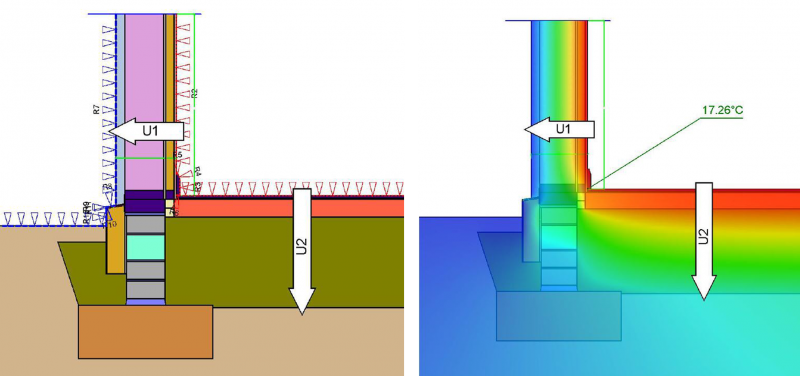

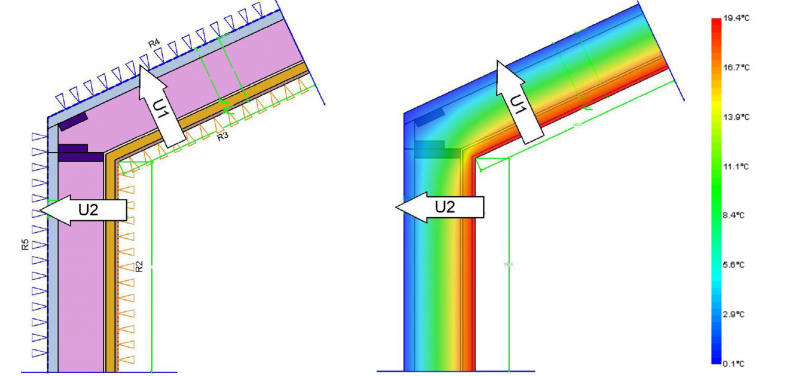

A thermal bridge occurs anywhere in the building envelope where the insulation layer is disturbed or altered due to a change in building fabric. The material penetrating the insulation layer usually has a higher thermal conductivity than the surrounding material. This creates the path of least resistance for heat to move across the thermal barrier, resulting in heat loss from inside the building.

Types of Thermal Bridges

There are three different types of thermal bridges that can occur within a build:

1. Non-repeating thermal bridges

These occur sporadically throughout the build when there is a break in the thermal envelope. These can be RSJ penetrating the insulation, steel column through the floor slab, and a load-bearing partition wall through the floor insulation.

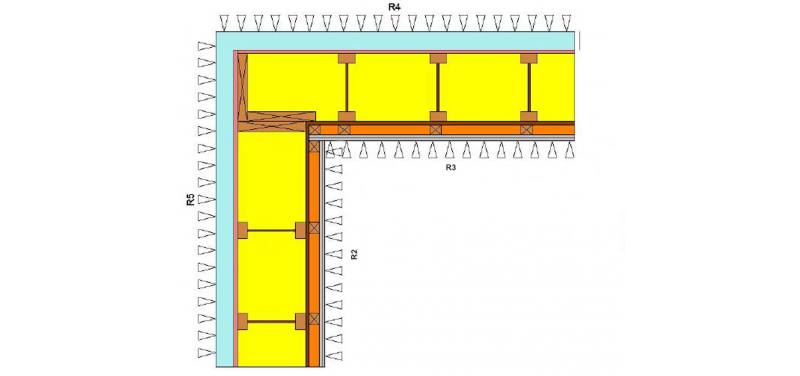

2. Repeating thermal bridges

These tend to be repeated over the entire building:

- Wall ties in a masonry build;

- Roof joists in a cold pitch roof detail where they interrupt the insulation at the ceiling level.

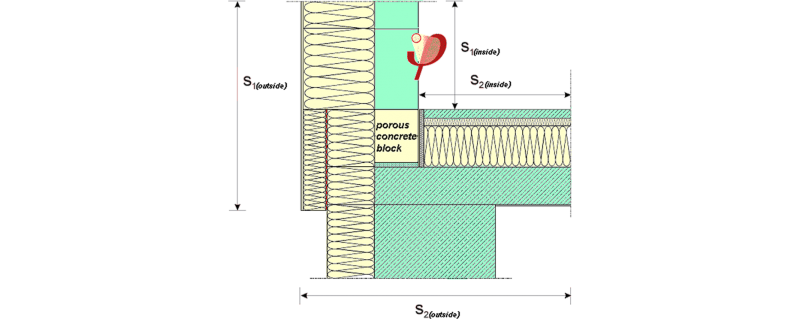

3. Geometric thermal bridges

These are due to the geometry of the building.

- Wall to roof junction or wall to floor junction. It is good to note keeping the overall building design simple tends to avoid geometrical thermal bridges.

Thermal bridging should be reduced as much as possible to reduce the amount of heat loss at these junctions and reduce the amount of energy required to compensate for this loss. Reducing the likelihood of thermal bridging also eliminates the risk of surface condensation and mould growth occurring, which in turn improves the longevity of building structure and occupant’s health.

What is a thermal bridge-free design?

A building envelope is free of thermal bridges if the transmission losses under consideration of all thermal bridges are not greater than the result calculated using the external surfaces and regular U-values of the standard building elements alone. Regularly occurring thermal bridges in standard building components must already be considered in the regular U-values. The general rule of thumb for Passive House buildings, however, is Ψ ⩽ 0.01 W/(mK).

How to prevent a thermal bridge?

Adding in a thermal break, or thermal barrier, helps block this heat pathway and prevents heat loss. Thermal breaks usually have a low thermal conductivity preventing the flow of heat.

Wrapping the building envelope with a layer of continuous insulation prevents thermal bridging. Observing and dealing with discontinuities of this insulation at junctions and openings can improve the heat loss of the overall building.

High-performance solutions to facilitate a thermal bridge free design

ALMA VERT is a high-performance innovative panel used for structural insulation. It is made of 95% recycled material – PET bottles, so can be easily recycled again at the end of its life cycle. Noted for its high compressive strength and its excellent mechanical strength, ALMA VERT is extremely efficient as a thermal break.

Thanks to its very low thermal conductivity of 0.036 W/mK, this ecological modular solution allows for thermal separation in both new build and retrofit projects.

ALMA VERT has a wide range of applications including:

- Under, above and around reveals of both windows and doors

- Around the perimeter of the building, ensuring a continuous insulation line

The recycled panel can be mechanically fixed, easily cut on-site, and it is also worth noting that it has a water absorption rate of less than 2%.

ALMA VERT is available in two different density classes (115kg/m3 and 180kg/m3) and can be supplied in two standard dimensions.

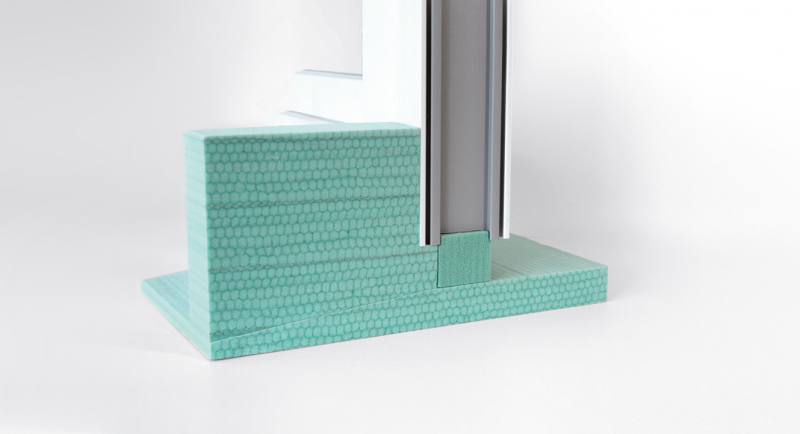

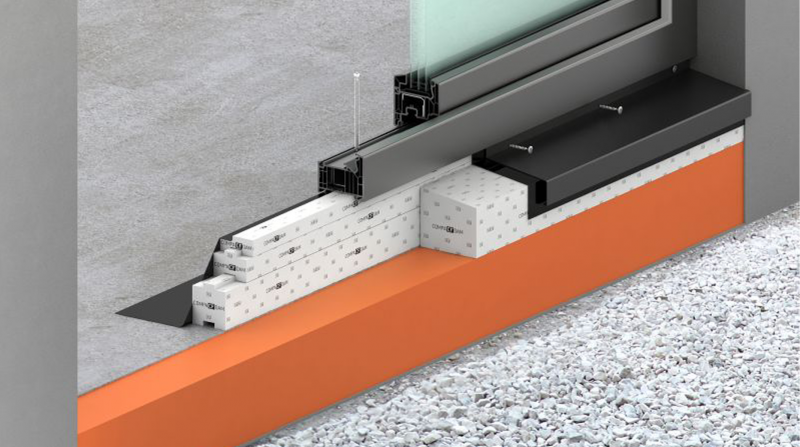

COMPACFOAM is a similar application product to that of ALMA VERT.

Its physical and chemical structure corresponds to that of expanded polystyrene (EPS). Tiny closed-cell foam balls of less than a millimetre in diameter are welded together thermally into a compact block. Compacfoam provides a high compressive strength and great thermal insulation.

With a wide range of applications like what is mentioned above and can be used to create a thermally broken pocket for a steel beam.

Compacfoam is manufactured in five density classes ranging from 100 to 400 kg/m3. The product variations include standard panels and depending on project requirements can create fabricated parts to that of the customer specifications.

AEROGEL Insulation is a nano-porous insulation designed to prevent heat loss and thermal bridging of residential and commercial building applications. It has properties that include a very low thermal conductivity, flexibility hydrophobicity and is generally a very easy product to work with. These characteristics make it an essential material for those who are looking for maximum thermal protection.

It is a great problem solver for a wide range of situations mainly used in the cladding of steel corner posts. It can be cut using conventional cutting tools making it a very easy material to install.

The products were already used in dozens of low-energy projects across Ireland, the UK, and North America proving their strength, insulation, and protection characteristics.

Conclusion

As building regulations advance, architects, designers, builders, and occupants become more energy conscious, further attention is placed on thermal bridging and their benefits at entry level to the homeowner. No matter if you are developing a new build or retrofitting an existing house, care should always be observed to minimise and eliminate any unnecessary thermal bridging.

References

https://passipedia.org/basics/building_physics_-_basics/what_defines_thermal_bridge_free_design